Managing bulk loads in demanding work environments is a challenging task that requires careful planning, effective strategies, and the right tools. Whether you’re handling raw materials in a factory, processing large data sets in a tech firm, or managing inventory in a warehouse, having the right approach can make all the difference in streamlining operations and improving productivity. In this article, we’ll explore several effective strategies for handling large volumes of work in fast-paced and high-pressure settings.

Understanding Bulk Loads in Demanding Work Environments

A “bulk load” refers to a large quantity of items, materials, or data that must be moved, processed, or stored efficiently. In demanding work environments, bulk loads can range from physical goods to data in digital formats, depending on the industry. For example, a manufacturing plant may have to manage bulk loads of raw materials, while a tech company may handle massive data files or large customer databases.

These environments often have tight deadlines, high expectations, and limited resources. Therefore, successfully managing bulk loads requires the implementation of processes that minimize inefficiencies and ensure smooth workflow. Whether you’re moving heavy objects, organizing data, or managing inventory, the right strategies can save time, reduce costs, and improve overall productivity.

Automation: The Backbone of Efficiency

In today’s fast-paced work environments, automation has become a cornerstone of managing bulk loads. Automation involves using technology, such as machines, software, or robots, to perform repetitive tasks that would otherwise require human labor. In manufacturing, automated systems can transport materials across the factory floor, reducing the time spent manually moving heavy loads. This not only speeds up production but also improves safety by minimizing human involvement in potentially dangerous tasks.

In data-heavy industries, automation tools can help manage and analyze large datasets quickly and accurately. Software systems designed to sort, analyze, and process data can save hours of work, allowing employees to focus on higher-level tasks. For example, automation can be used to automatically sort inventory, reducing human error and improving the accuracy of stock counts.

While initial costs for automation technology can be high, the long-term savings in terms of time and labor costs often make it a worthwhile investment. As industries continue to embrace automation, its role in managing bulk loads will only grow.

Streamlining Processes to Reduce Bottlenecks

Even with automation, human involvement is still crucial in managing bulk loads. This is where process streamlining comes into play. In any high-demand environment, bottlenecks can slow down progress, causing delays and wasting valuable resources. Bottlenecks occur when certain parts of the process slow down the entire system, preventing smooth operation.

To reduce bottlenecks, it’s essential to map out workflows and identify areas where slowdowns occur. This could involve analyzing the time it takes to move materials from one stage of production to the next or determining which steps in the data processing pipeline take the longest. Once these bottlenecks are identified, steps can be taken to address them.

For example, in a warehouse setting, introducing more efficient shelving systems or optimizing the layout of the space can prevent congestion. Similarly, in a tech environment, optimizing the data processing pipeline by upgrading hardware or implementing parallel processing can help speed up the system.

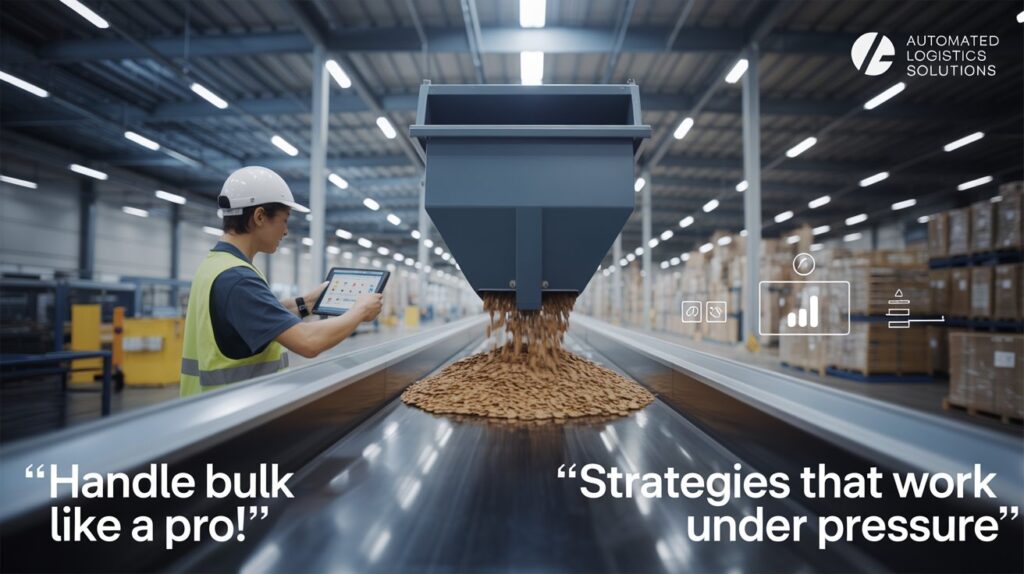

Leveraging Self Dumping Hoppers for Material Handling

In environments where heavy loads and bulk materials are constantly moved around, tools like self dumping hoppers play a critical role in improving efficiency. The hoppers are designed to help workers transport and dispose of bulk materials quickly and safely. These hoppers can automatically dump their contents when raised to a certain height, reducing the need for manual labor and preventing workers from performing risky tasks such as lifting heavy loads.

Self dumping hoppers are especially useful in manufacturing and construction industries where large volumes of waste, scrap, or materials need to be handled efficiently. By integrating these tools into material handling processes, companies can not only increase productivity but also reduce worker fatigue and minimize workplace accidents. This small adjustment can have a big impact on managing bulk loads effectively.

Real-Time Monitoring and Data Analytics

In high-demand environments, real-time monitoring is essential for managing bulk loads. This involves using technology to track and monitor the movement of materials, inventory, or data in real time. By doing so, companies can gain insight into their operations, making it easier to identify and address issues as they arise.

For example, inventory management systems equipped with real-time tracking allow warehouse managers to know exactly where materials are located, how much stock is available, and when it’s time to reorder. This prevents stockouts, reduces waste, and improves overall workflow.

In data-heavy industries, real-time analytics can be used to monitor system performance and identify potential issues with data processing. Software solutions that track data flow and system performance can provide alerts when something goes wrong, enabling IT teams to take immediate action.

This kind of real-time data is invaluable in fast-paced work settings because it ensures that decision-makers are never in the dark about what’s happening at any given moment. It allows for swift, informed decisions that can prevent delays and streamline operations.

Employee Training and Involvement

While automation, tools, and technology are essential in handling bulk loads, the human factor cannot be overlooked. Employee training plays a significant role in improving efficiency and managing large volumes of work. Properly trained employees are more likely to make fewer mistakes, work faster, and be more efficient in their tasks.

It’s important for companies to invest in ongoing training programs that ensure employees are well-equipped to handle the demands of high-pressure environments. This can include safety training for material handling, as well as skills development for using automated systems and managing data.

Employee involvement in decision-making also enhances productivity. When workers feel like they are part of the process and have a say in how things are done, they are more motivated and invested in the success of the company.

Emphasizing Safety and Risk Management

Handling large volumes of work often involves significant physical labor or dealing with complex systems, both of which come with safety risks. In manufacturing and construction, workers may be exposed to heavy machinery, dangerous materials, or high-risk environments. In data-heavy environments, there are risks associated with cyber threats, data breaches, and system failures.

Safety protocols and risk management practices must be integrated into the strategies for managing bulk loads. This includes using personal protective equipment (PPE), conducting regular safety audits, and having contingency plans in place for emergencies. Ensuring that workers are properly trained on safety procedures and that the workplace is equipped with safety measures helps reduce the risk of accidents and increases overall efficiency.

Conclusion

Effectively managing bulk loads in demanding work environments is no easy task, but with the right strategies, it can be done efficiently. From automation to real-time monitoring, and from process streamlining to employee training, the key is to stay ahead of potential issues and proactively implement solutions that reduce inefficiencies.

By integrating tools like self dumping hoppers into material handling processes and embracing the latest technology, companies can create smoother, more efficient workflows. With a focus on safety, employee involvement, and continuous improvement, businesses can effectively navigate the challenges of high-demand work environments, turning them into opportunities for growth and success.