The importance of reliable heat exchange cannot be overstated in the food and beverage industry, where precision temperature control plays a vital role in both the quality and safety of the end products. Plated heat exchangers represent a significant leap forward in thermal technology, offering a range of benefits from efficiency to hygiene. As producers seek to optimize their operations and adhere to stringent health standards, these innovations become increasingly crucial. Below, we explore the multiple advantages that plate heat exchangers provide to food and beverage processors.

Understanding Plated Heat Exchangers and Their Role in Food Processing

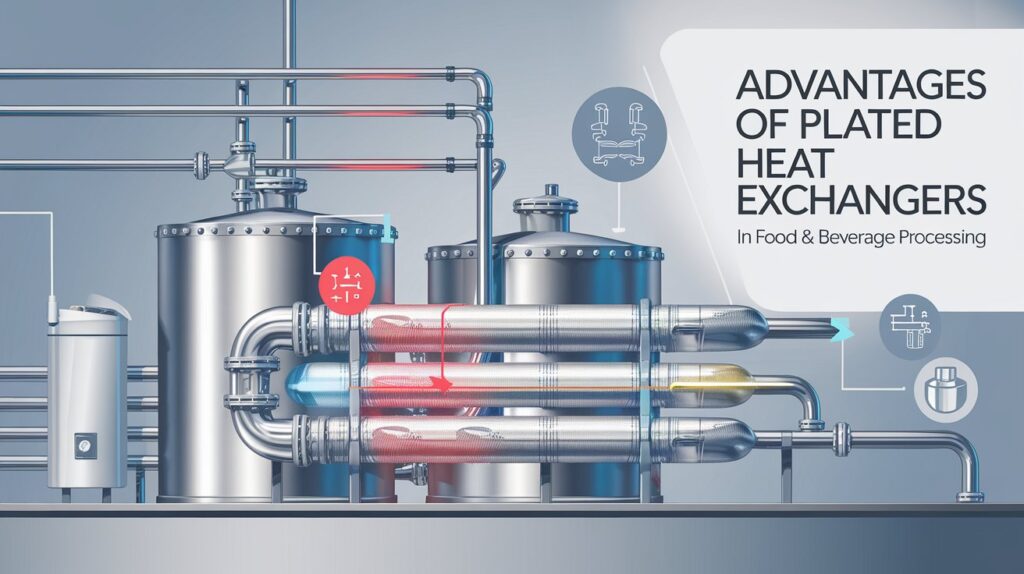

Plated heat exchangers, with their compact design and high heat transfer capabilities, are essential in food processing to manage temperature-specific tasks. Their core function is to transfer heat between two fluids, which are kept separate by plates to prevent cross-contamination — a crucial consideration in food production. These devices efficiently handle heating and cooling processes, which are integral in pasteurization, fermentation, and various other stages of food preparation.

The design of plated heat exchangers allows for their use in applications where space is at a premium, as they have a smaller footprint than other types of heat exchangers. Plated heat exchangers for processing are ideal for quick temperature changes, which is beneficial for products that are sensitive to heat exposure. Moreover, their construction typically includes stainless steel plates, which are not only durable but also meet the food industry’s hygiene standards.

Their modular design means that these heat exchangers can be easily expanded or modified to suit changing production demands. This flexibility is valuable for food processors who need to scale operations or adjust processes to accommodate different products. The ease of access to the plates also simplifies cleaning and maintenance, which helps maintain food safety and extends the equipment’s service life.

Ensuring Food Safety With Improved Temperature Control

Food safety is non-negotiable in the food and beverage industry, and precise temperature control plays a pivotal role in maintaining it. Plated heat exchangers excel in providing accurate temperature regulation, fundamental in pasteurization processes that eliminate harmful bacteria. Through consistent heating and cooling, these devices ensure that food products meet the necessary safety standards before reaching consumers.

Because plated heat exchangers are designed for quick and uniform temperature changes, they help to avoid the danger zones where pathogen growth is most likely to occur. This capability is crucial in processes like chilling, where rapid cooling is necessary to prevent spoilage. Moreover, the physical separation of plates means there’s little risk of cross-contamination between the heating and cooling mediums.

The ease of cleaning is another safety advantage of plated heat exchangers. Accessible plate designs enable thorough sanitization, critical for eliminating any bacterial build-up and ensuring that food safety is not compromised. A clean heat exchanger reduces the risk of product recalls, which can be costly and damaging to brands.

Cost-Effective Maintenance and Energy Savings in Beverage Processing

Beverage processors, particularly those in the dairy and brewing industries, can see substantial cost benefits when using plated heat exchangers. These devices typically have lower installation costs than their bulkier counterparts and offer a higher return on investment due to their operational efficiency. The reduction in both energy usage and utility costs makes these units an economically sound choice.

The maintenance of plate heat exchangers is less labor-intensive compared to other types of heat transfer equipment. Plate packs can be easily removed, inspected, and cleaned without the need for specialized equipment or significant plant downtime. This operational convenience can equate to sizeable cost savings over the lifecycle of processing equipment.

Meeting Industry Standards and Regulations With Advanced Heat Exchange Solutions

The food and beverage industry is governed by a complex web of standards and regulations, many of which relate directly to temperature control and equipment sanitation. Plated heat exchangers help businesses meet these requirements efficiently. They can be tailored to satisfy the specifications of various regulatory bodies, ensuring that processors remain in compliance and avoid potential legal ramifications.

As regulations evolve to demand higher efficiency and lower emissions, the technology behind plated heat exchangers keeps pace. The adoption of these systems supports efforts to reach environmental targets and minimize carbon footprints. Companies that integrate such advanced technologies demonstrate a commitment to innovation and responsibility, which can enhance their reputation and marketability.

Altogether, the integration of plated heat exchangers into food and beverage processing not only elevates operational efficiency but also fortifies the dedication to product quality and safety. These versatile units are pivotal in helping the industry meet the growing challenges of regulatory compliance, environmental stewardship, and consumer demand for superior products.